When TEC Cables are taken outside their usual surroundings, deep underground, under the water, inside the heavy machines, or over hot industrial floors, the whole situation gets changed. Just normal cables are not enough for such places. Hence, tubing-enclosed wires come into the picture. These wires with an additional protective layer wrapped around them are basically very detailed and heat-, pressure-, chemical-, and moisture-resistant, as well as resistant against the continuous mechanical stress.

Though, thick-covered tubing wires are not the same. The right one is not just about which of the options is the thickest. It refers to knowing the surroundings, the dangers, and the technical side of the work. Here, by means of this manual, you will be able to understand how to find great and strong tubing-encapsulated cables without being flooded with difficult words.

Understanding What Makes Tubing-Encapsulated Cables Different

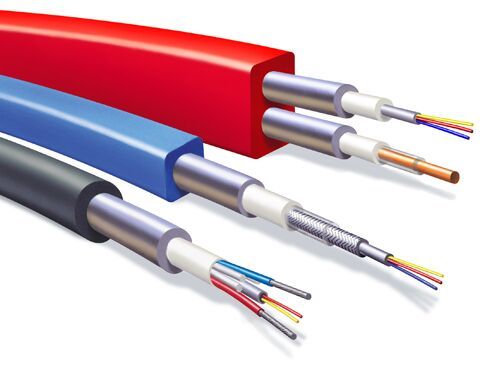

Tube-encapsulated cables are normally electrical or data cables put into one protective tube that is made from specialized materials like stainless steel, thermoplastics, fluoropolymers, or reinforced polymers. This outer tube is a kind of protection from the environmental factors and at the same time, it increases the mechanical strength.

Moreover, traditionally the main function of the insulation is to prevent the electricity leakage; however, in the case of tubing, the aim is to defend the cable from physical attack, chemical corrosion, being crushed and also from very hot and cold weather. Because of that, the cables find a vast market in use in such industries as oil and gas, mining, defence, marine engineering, renewable energy, and heavy manufacturing.

Define the Extreme Conditions First

Prior to the lighting up with a cable choice, it is necessary to come up with a clear definition of "extreme" that accurately fits your job or equipment. The concepts of extreme conditions are very different and each requires its own specific method of protection.

Consider these questions and be honest with yourself:

- Will the wire be heated or cooled for a long time?

- Will it be constantly subjected to the vibration, bending, or movement?

- Will it be allowed to swim in water, and will it be exposed to moisture, salt, or steam?

- Are there any exposures to chemicals, oils, or acid and, if yes, are the kinds well known?

- Is it possible the cord will be squeezed, dragged, or even hit with sharp objects?

- Do you have to worry about EMI (electromagnetic interference)?

The more you know about those working conditions, the better will be your encapsulation and internal cable structure choice.

Choose the Right Tubing Material

The following part of the defence is the outer tube. Its substance is what fundamentally decides cable life in the cruel environment.

Stainless Steel Encapsulation

This is the best choice to use for radical mechanical stressing, high-pressure situations, and cases where destruction caused by rodents, abrasions, or crushing is a concern. Also, the stainless steel tubing is capable of withstanding very well extremely high temperatures and acid industrial areas.

Meanwhile, it is heavier, less flexible, and more costly. Therefore, it is mainly used in fixed installations where there is no or minimal bending/stretching of the cable.

Thermoplastic Tubing

Thermoplastics like PVC, PU, and nylon are light in weight, flexible, and affordable. They provide decent wear and tear, water resistance, and moderate chemical exposure protection. These are the products that are mostly implemented in the areas of automation, robotics, and factories, where the movement is kept up constantly.

They may not be very suitable for hot areas or for highly corrosive ones.

Fluoropolymer Tubing

One of the choices that gives the best protection against the introduction of the chemicals, solvents, moisture and the usage of extreme temperatures are the products of the fusial polymers industry like PTFE, FEP, or PFA. These are very common in the aeronautics, medical equipment and chemical industry sectors.

They are more costly but give long-lasting reliability when chemical resistance and thermal stability are must-haves.

Certification and Testing Are Necessary

In harsh situations, certifications are what matter. Depending on your usage, take note of the cables that are tested and certified for fire resistance, oil resistance, UV stability, chemical resistance, and environmental sealing.

Testing standards are not only there for the paperwork they feature—they show that the cable has been verified under specific conditions of stress. This lessens the degree of unknowns and makes the whole system safer.

Longevity and Total Cost of Ownership

Once in a while, durable tubing-encapsulated cables may be priced higher at the point of sale. But, as a result of repeated cable failures, the overall cost greatly increases due to production downtime, safety risks, and expensive replacements. Thus, high-quality cables make long-term savings possible, as they are a lot more reliable.

What if the company runs on a 24/7 basis, then a cable failure could lead to the production being stopped, the safety of workers being compromised or sensitive equipment getting damaged. Therefore, in such a situation, durability cannot be considered as a mere luxury.

Customization for Unique Applications

Most of the time, in the situations where you have extreme environments, off-the-shelf cables are not sufficient to fulfill the exact requirements. By means of a custom tubing-encapsulated cable, you would be able to provide specifications for real-world situations such as tubing thickness, material type, the structure of the internal conductor, shielding, and connector design.

Customization is the most useful feature just in case of the defence, aerospace, subsea, or high-temperature industrial applications where standard cables cannot last without failing.

Final Thoughts

Deciding on resilient tubing-wrapped cables for harsh conditions is more than just a technical choice; it's a reliability and safety decision. A suitable cable is the one that keeps your machinery, data, and work schedule safe from the harsh environment, which in no time would demolish standard wiring.

By paying close attention to temperature exposure, mechanical stress, chemical resistance, environmental sealing, and deciding if the place for the installation is feasible, you will still have the upper hand in the cable durability game for years and not for months. The purpose is not to merely survive under extreme conditions but rather to have the confidence of operating within them without the need for constant maintenance, failures, or costly downtime.

Ultimately, durable Tubing Encapsulated Cables represent a bet for tranquilly. If done right, they continuously perform the work without interruptions; thus, they provide security to the core systems and make available the unhampered functionality in places where regular cables would fail instantly.

Also Read: Top Uses of Armoured Cable in Residential and Industrial Wiring